Projects

Here are some projects illustrating my past years at Bureau Veritas, CGN Europe Energy, and GE Vernova

Major wind turbine blade damages

I participated in several in-depth analyses concerning major wind turbine blade damage.

At CGN Europe Energy, I provided technical support following incidents related to failures in the lightning protection system. My experience in the certification of blades and their subsystems, acquired at Bureau Veritas, allowed me to assess the manufacturer’s analysis.

At GE Vernova, I was responsible for the root cause analysis after a major damage incident led to the replacement of a blade. I coordinated the on-site technical teams responsible for sample collection and the design engineers in charge of the analysis.

These assignments allowed me to develop a robust expertise in root cause analysis applied to critical wind turbine components, combining field observations, data exploitation, and stakeholder coordination to ensure reliable and secure decision-making.

Mechanical defects

At GE Vernova, I specialized in managing mechanical non-conformities such as assembly loosening, crack initiation, and corrosion phenomena. I was responsible for leading root cause analyses on major issues, some of which required the implementation of large-scale repair and retrofit campaigns.

My role was to ensure coordination between the field teams, responsible for conducting inspections and collecting data, and the design engineers. I was responsible of the definition of corrective action plans and for the coordination of their execution.

This experience allowed me to develop an in-depth expertise in the management of complex mechanical failures, combining technical diagnosis, problem resolution, and project management for retrofitting critical offshore wind turbine components.

Asset management

At CGN Europe Energy, I provided support for setting-up an Asset Management System compliant with the ISO 55001 standard. I participated in the design of procedures intended to organize the management of wind and solar farms around internationally recognized best practices.

I contributed to defining and documenting key processes related to monitoring, operation, maintenance, and continuous improvement of assets, specifically integrating concepts of risk management and cost optimization.

Furthermore, I conducted internal audits to assess the compliance of existing practices with the standard’s requirements, identify gaps, and propose corrective actions. These audits also helped raise awareness among operational teams about the certification requirements.

With this project I gained experience in implementing an Asset Management framework, combining documentary analysis, field verification, and team coaching toward achieving certification.

Monitoring system deployment

At CGN Europe Energy, I led the acquisition and deployment of a new supervision tool for the company’s wind and solar portfolio. I first conducted a comparative testing phase on four existing solutions—QOS Energy (now Bazefield), Envision, Greenbyte (now Power Factors), and Scada International (now Opoura)—to evaluate their performance and suitability for operational needs.

After the selected solution was chosen, I oversaw its deployment across the entire 2.4 GW portfolio, which included the integration of historical data and the implementation of controls to ensure the quality and reliability of the collected data.

This project provided the company with a centralized and robust platform, paving the way for better data utilization, participation in digitalization research programs, and the development of innovative predictive maintenance projects.

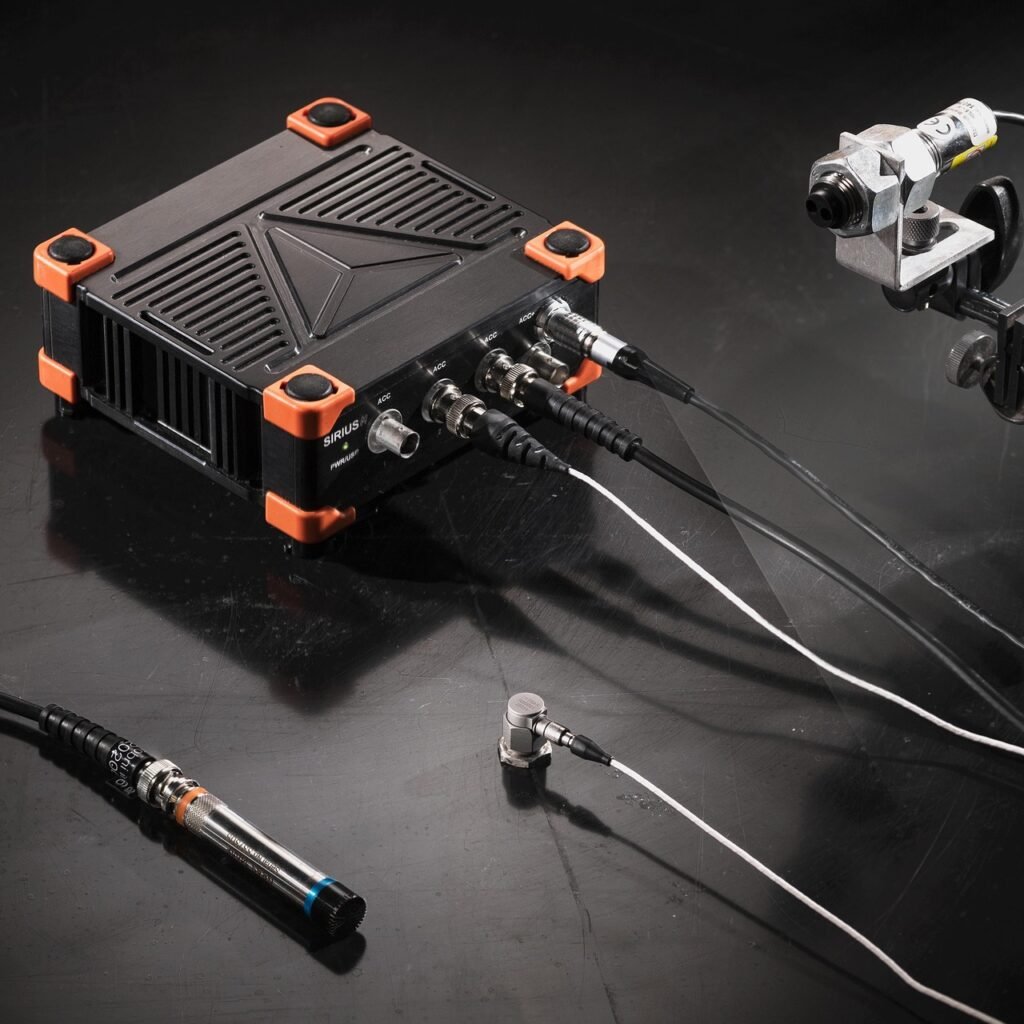

Measurement campaign

Among my assignments at GE Vernova, I participated in measurement campaigns aimed at validating the choice of technical solutions. I was responsible for defining the specifications in collaboration with the designers to ensure the relevance of the tests. I then managed the on-site installation of sensors (for displacement, acceleration, and stress), ensuring the quality of their implementation and compliance to protocols. Finally, I supervised the post-processing of the collected data, allowing for the extraction of necessary insights to validate the solutions under study.

Main shaft inspections

At Bureau Veritas, I managed the follow-up of a ShafTest® inspection campaign on a fleet of wind turbines. The objective of this assignment was to check the integrity of the low-speed shafts and verify the potential presence of fatigue-related cracks. I acted as the main contact point between the technical teams to ensure the reliability of the measurements and the analysis of the results.

Foundation inspections during construction phase

At Bureau Veritas, I conducted inspections of wind turbine foundations to ensure their compliance with turbine manufacturer recommendations and industry best practices. I checked the reinforcement steel (rebar) before concrete pouring, specifically checking the quality of the installation and compliance to the execution plans.

My on-site presence during the concrete pouring allowed me to support the construction teams, quickly identify any non-conformities, and propose immediate corrections. This assignment contributed to securing the structural quality of the foundations.